GODN is the Industrial Spraying Machine manufacturer & supplier, and a Spray Finishing Solution Provider for Wood, Metal, Furniture & Building Industries.

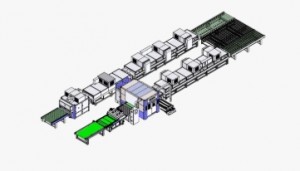

Through the years, our product range has been extended to include automatic spraying machines, drying machines, and complete spraying lines, which are widely applied in the furniture industry.

A professional and high-educated R&D team gives us a superior advantage in providing customized SPRAY FINISHING solutions. Continuous improvement in production and quality leads to reliable machines built in state-of-the-art facilities.

Automatic Spray Coating Line – Advantages

Our systems combine advanced spraying technologies with smart controls, designed for the wood, furniture, door, and cabinet industries. Configurations can include:

- Oscillating spray coaters – efficient and versatile for small to medium production volumes.

- Rotary / elliptical spray coaters – high-throughput systems for large-scale operations.

- Robotic spray arms – ideal for complex shapes and precise, repeatable applications. Two robots can work simultaneously on the same piece to boost efficiency.

- Integrated handling and drying systems – conveyors, loading/unloading solutions, and curing equipment to ensure a smooth workflow.

Automated finishing system for wood spraying

The paper configuration is recommended for

non-recoverable paint or glue finishes.

The roll of paper, on high-capacity reels,

has an electronically controlled pay-off,

take-up and tensioning system.

an impressive look and a natural feel.Whether you manufacture furniture, kitchens, stairs, windows or doors from solid wood or produce wood-based materials, we have just the right paint or varnish or your spray painting machine.

an impressive look and a natural feel.Whether you manufacture furniture, kitchens, stairs, windows or doors from solid wood or produce wood-based materials, we have just the right paint or varnish or your spray painting machine.

Technical Setup: Flatbed spray painting machines are complex pieces of equipment and there are numerous parameters that need to be considered when setting them up, for example the spray nozzles, pistol system, material pressure, atomising air, belt speed, number of strokes and the height of the nozzles. There are a wide range of factors that can have an impact on the results of the coating process, so it is essential that the system is correctly set up to prevent the formation of streaks, drips or cloudy areas and to ensure even application.

The feed also needs to be adjusted to suit the carriage drive. These and many other factors need to be taken into account. With support and guidance from GODN, it will be very easy for you to find the right paint or varnish for your flatbed spray painting machine. Get in touch with us!

For those who have sprayed by hand until today, the reciprocating spray machines are the ideal tool to produce this water based finish for small to high volume outputs, due to their wide-reaching variety of benefits:

- Modular Design: These modular spray machines come fully equipped with a high-precision photodiode reading barrier for scanning in the incoming objects for spraying and are available in a number of standard multiple gun single or twin arm spray head configurations.

- Material Versatility: Wide variety of substrate materials can be operated on (various woods, plastics and metals).

- Process Optimization: Regardless of the size and material of the piece being processed, the precise scanning which the control software affords will optimise the spray painting process.

- Cost Efficiency: Cost-efficiency is maximised throughout, by negating the wastage of paint.

- Durability: Because water-based paints remain flexible, they can accommodate regular movement – making them more durable and long-lasting.

- Moisture Management: Due to their water vapour permeable, microporous nature, water trapped beneath the surface of these paints allow trapped moisture to evaporate naturally.

- Operational Flexibility: Water based spray painting machines are the ultimate tool for affording flexible performances – through the easy management of small to medium sized batches and frequent, easy colour changes.

- Consistent Finishing: Any enterprises which require consistent, uniform finishing can benefit from these advanced systems.

Post time: Dec-31-2025